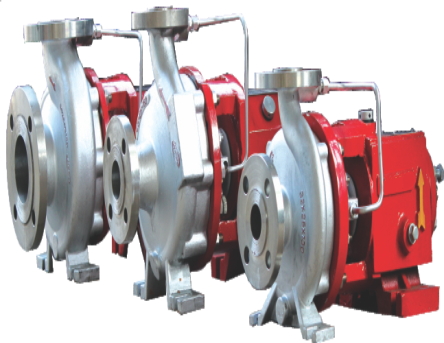

MARCK-MFP-SERIES

“MARCKPumps” series MFP pumps are the centrifugal type with semi-open non-clogging impeller pump comes with single row deep grooved heavy duty antifriction ball bearing with oil lubrication. We have specially designed for the industry that curves for the power cost easy maintenance with replaceable parts.

Only for positive suction head.

Feature:-

•Semi-open type impeller design to handle slumies with solids

•Side Suction & Top Discharge connection

•Least Leakage due to gland portion on Suction Side

•Harden & Grind Shaft gives longer life

•Heavy duty Oil lubricated bearing housing

•Available in All CI, CI/SS, and SS-316 moc

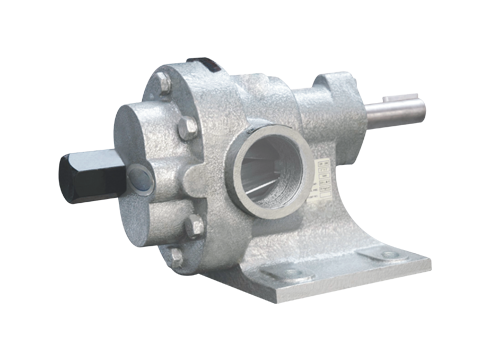

Application:-

•Ideal for Filter Press applications in Dyes, Intermediates,

•Scabber and Spary Drayer Application.

•Chemicals, Textiles, Ceramics etc. industries

•Oil & Petrochemicals Industries

•Effluent Treatment Plants

•Transferring, Loading, Unloading of Chemicals, Light Petroleum Products etc